Ceramic Fibre Paper

Introduction

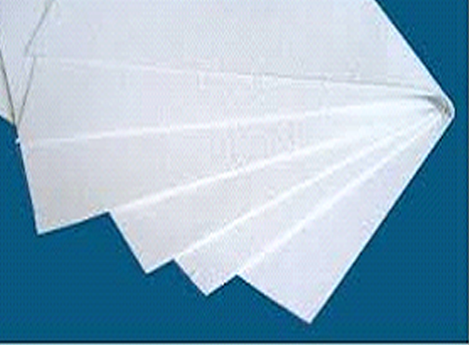

KSG ceramic fiber paper product line is a unique family of products which is manufactured by forming alumina silicate fibers in a nonwoven matrix. The ceramic fibers are randomly orientated during manufacture, and then held in place with a latex binder system.

KSG specialized paper making process is statistically controlled to form uniform, lightweight, flexible sheets. By blending different fibers, binders, and additives while varying the manufacturing process.

KSG now produces a variety of KSG paper products for a wide range of applications. KSG papers exhibit excellent chemical stability, resisting attack from most corrosive agents. Exceptions are hydrofluoric, phosphoric acids and concentrated alkalis.

KSG papers are wet by water or steam, all thermal and physical properties are completely restored upon drying. No water of hydration is present in most KSG paper grades. Our papers have good dielectric strengths. KSG papers, with the exception of the inorganic series, will generate small amounts of smoke and trace element outgassing during the initial exposure to temperatures above 450°F.

Applications

KSG ceramic fiber papers offer our customers many unique problem-solving advantages which include.

High-temperature stability

Low thermal conductivity

Low heat storage

Weight reduction

Resiliency

Thermal shock resistance

High heat reflectance

Good dielectric strength

Excellent corrosion resistance

Easy to wrap, shape, or cut

Highly efficient refractory backup

Dependable fire protection

Thermal insulation

Hot gas filtration media

Molten metal splash and spark protection

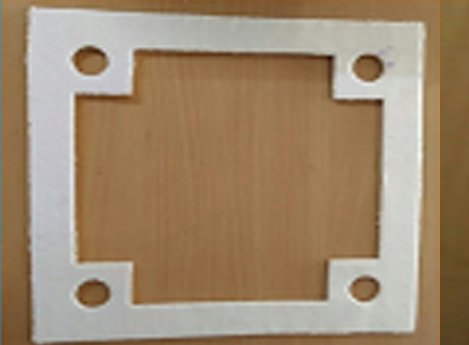

High-temperature gasket, separator, or parting agent

Heat shields

Nose cone ablative shields

Igniter line protection

Oxygen generators Appliance

Self-cleaning ovens

Wood burning stoves

Electrical heaters

Ware separator

Metal clad brick gaskets

Glass tank refractory backup Petrochemical

Transfer line protection

Welding

Brazing protection Automotive

Muffler insulation

Heat shielding Steel and Nonferrous

Investment casting mold wrapping

Ladle refractory backup

Thermocouple tube protection

Heat treating parting agent

Foundry gasketing

Ladle shroud wrap

Main Properties

Ceramic Fiber Paper

| Physical Properties | NOR |

| Classification temperature ° C | 1260 |

| Chemical composition (%) | |

| Al2O3 | >40 |

| SiO2 | <60 |

| ZrO2 | - |

| Loss on ignition % | <10 |

| Density (Nominal) kg/m | 200 |

| Tensile Strength (psi) | >90 |

| Linear shrinkage % - 24 hrs | 4 |

| (Max) (ENV 1094-7) | (1200°C) |

| Color | Cream to Tan |